You know the old saying.

Garbage in, garbage out.

GIGO, if you need to put an acronym on it.

When businesses record, store, process, and output data, the quality of the result largely depends on the quality of the input.

Is your data accurate, consistent, and complete?

More specifically, as a CEO, CIO, Asset Manager, or Maintenance Manager, is your asset management data structured to meet your business needs?

Or is it garbage?

Functional Locations

We could speak in high-level abstracts about normalized data.

But let’s go the other way. A specific low-level example can illustrate the entire issue.

In a Maintenance Management System like SAP®, the Functional Location (FLOC) is the key field that identifies the location of a business function, like a pump on a cooling water system or a pressure relief valve on a compressed air tank.

We also attach significant master data and default workorder data to the FLOC field, including:

- Plant

- System

- Subsystem

- Cost Centre

- Equipment criticality

- Default planner group

- Work Centre

- Ect.

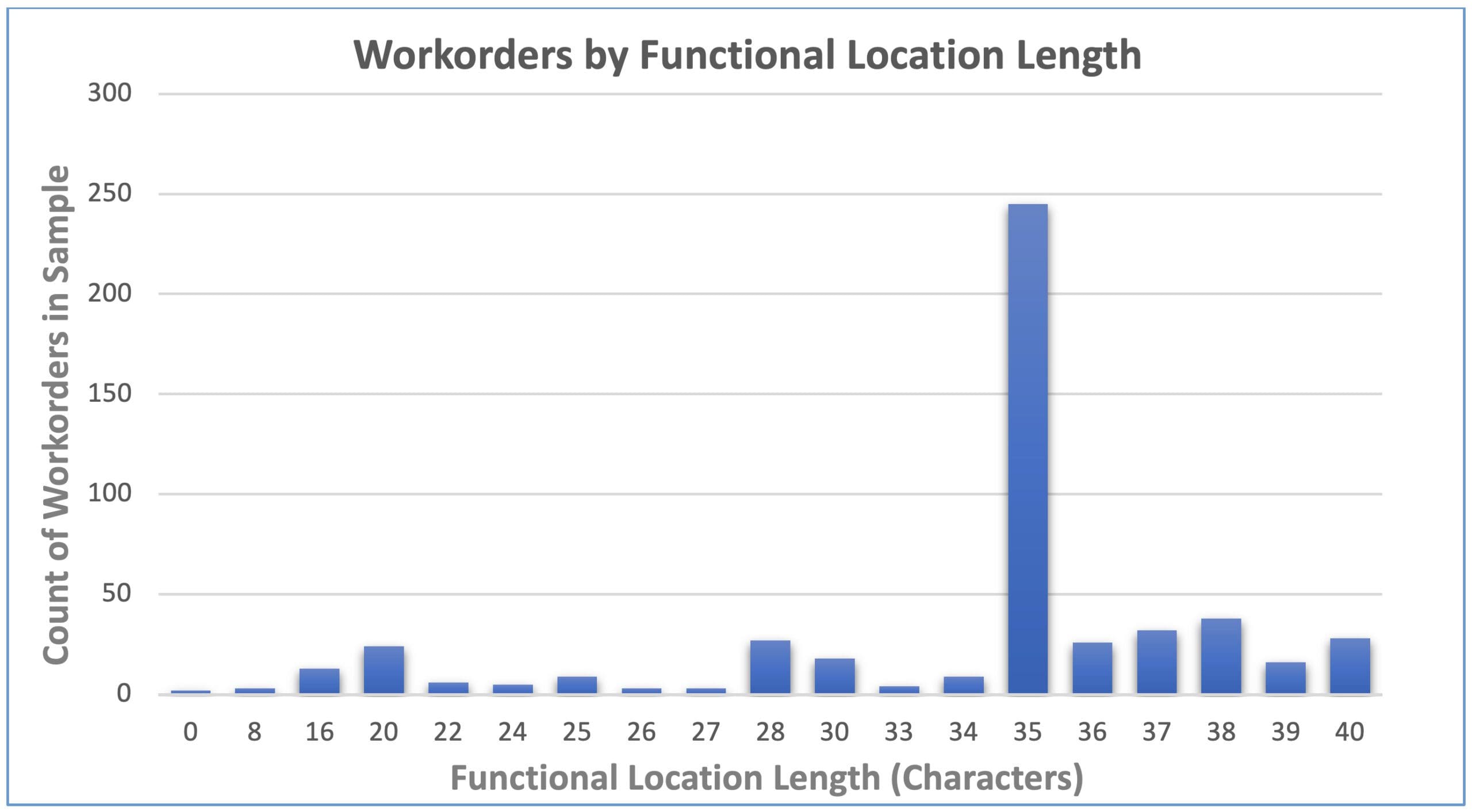

Below is a chart that displays FLOC lengths and how many workorders have a FLOC of that length. It’s based on actual data from a recent EAM Assessment.

This chart will be available on your operational dashboard or can be created by loading a list of all open workorders into Excel.

Some issues the chart highlights:

- Many of the workorders are attached to a FLOC with a length of 35 characters. If a 35-character FLOC consistently identifies the maintainable equipment in the plant, then this is ok. But we’d prefer to see all workorders with a 35-character FLOC.

- Many of the FLOC lengths vary by one character—usually from poor governance around the FLOC and master data. This data inconsistency could become a safety, regulatory, or production risk to your business.

- There are a couple of workorders with a FLOC length of 0. That’s a problem. Without an accurate FLOC, the system cannot attach the correct master data. These workorders will be lost in the system – not good if it’s a critical piece of equipment or a high-priority job.

This chart is easy to generate and provides a quick way to do a health check on the quality and management of your master data.

Need Help?

At Rizing, we help managers of high-capital value assets improve their business performance and gain better value from their fixed and IT assets. If we can help you with further information about Functional Locations or asset management, please contact Rizing or the author directly via email (david.harrison@rizing.com).