Chapters in this Series:

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10

This is the seventh in a series of 10 articles addressing the benefits of integrating a Geographic Information Systems (GIS) system with SAP®.

Material Traceability Defined

Material Traceability is having traceable, verifiable, and complete data. For assets such as gas transmission pipelines this set of data includes:

- Material attributes and manufacturer batch attributes

- Test / inspection results

- A history of inventory movements from manufacturer, to supplier, to storage, to job site, to its precise current location in a pipeline network

- Please see PHMSA excerpt at the end of this post for requirements

For many organizations, accessing this information digitally rather than searching hard-copy documents is more of a wish than a reality.

Successful implementation of a material traceability solution requires documented business processes and cross-functional coordination.

Critical Material Traceability Components

An ERP system such as SAP® and a GIS system for location information are critical components of a material traceability program.

We also recommend a document management system for storing key digital documents.

Material Traceability Process

An end-to-end process includes:

- Establish materials to be tracked in batches and those to be serialized

- Procurement of materials

- Receipt and storage of material and quality Inspection results

- Consumption of batches and serialized materials via work order

- Pass material and batch quantities as well as material and batch characteristics to GIS via interface

- As-built process in GIS mapping features and attribute values without re-keying data supplied by interface

- Passing of features and attribute location back to SAP from GIS via two-way interface

- Creation / change of functional locations and equipment with LAM values including batches as linear characteristics via SAP – GIS interface

- Ability to report serial number history

- Ability to track batch movement including return to SAP with precise location of batches throughout network

- Use of both SAP and GIS for reporting:

- Serial number history

- Batch inventory movements and location information

- Spatial analytics enabling batch performance vs. location / environmental / climate factors

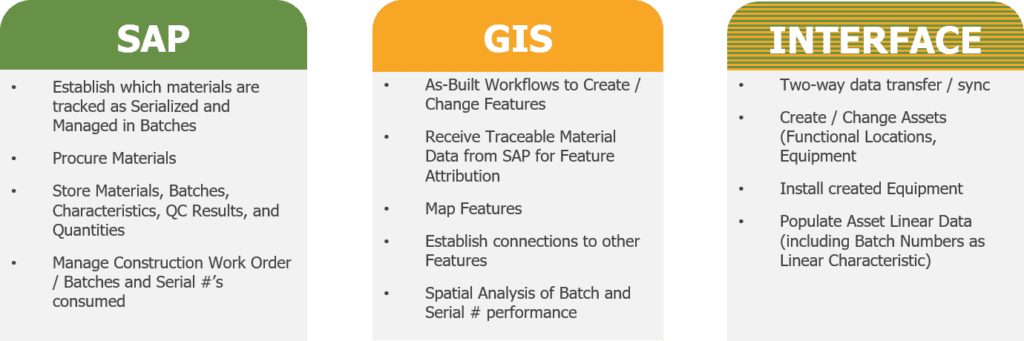

Role of each system in Material Traceability

Primary Benefits:

- Meet compliance / regulatory requirements

- Standardize business processes across functions

- Support where used and where in network reporting

- Avoid usage of unapproved materials

- Create traceable, verifiable, complete records

- Spatial Analytics of Material performance vs. climate, environmental factors

- Scalable solution for future initiatives

If material traceability was easy, more companies would already have well-established processes. If your company already owns SAP and a GIS application, a solution may not be far off.

Material Traceability To-Do:

- Companies must still work with Suppliers for proper labeling / barcoding of material

- Discipline must be established to track batches and serial numbers for all physical movement from receipt to storage, to job site, to precise installation location

- Scrapped or leftover remnants must be accounted for

- Mobile devices and label scanning is a must

Key Takeaway?

GIS and SAP are entirely capable of enabling and supporting material traceability.

Docket No. PHMSA-2012-0068, Pipeline Safety: Verification of Records

An owner or operator of a pipeline must meet the recordkeeping requirements of Part 192 and Part 195 in support of MAOP and MOP determination. Traceable records are those which can be clearly linked to original information about a pipeline segment or facility. Traceable records might include pipe mill records, purchase requisition, or as-built documentation indicating minimum pipe yield strength, seam type, wall thickness and diameter. Careful attention should be given to records transcribed from original documents as they may contain errors. Information from a transcribed document, in many cases, should be verified with complementary or supporting documents.

Chapters in this Series:

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10